A hydraulic structure is a facility designed for using water resources, as well as controlling the destructive effect of water. A dam, a hydroelectric power station, a drainage station, a drainage channel or, for example, a shipping lock can act in its role. Such buildings require careful monitoring according to various standards and regulations prescribed in GOST R 55260.1.4-2012 in order to avoid all types of emergency situations.

Monitoring the safety of hydraulic structures is a rather broad concept. It reveals the process of continuous monitoring of a facility throughout its entire life cycle in order to solve a whole set of critical tasks:

- ensuring continuous and uninterrupted operation of both the entire building and its single functional elements;

- monitoring status parameters and diagnostic criteria indicating the level of various risks;

- development and study of the effectiveness of single processes for ensuring accumulation and transfer of experience;

- monitoring the compliance with mandatory requirements in terms of fire and industrial safety.

The quality and quantity of monitoring procedures varies depending on the hazard class of hydraulic structures. For example, hydraulic structures of groups I, II and III need continuous and automatic monitoring.

These include earth dams and dams over 20 m high, flooding and dry docks, ice protection structures and sea berths. Hydropower complexes, such as hydroelectric power plants, also need monitoring.

Structural Health

Monitoring

System monitors

Organizing monitoring the safety of hydraulic structures is a whole set of procedures with two primary objectives. The specialists responsible for its implementation must, firstly, ensure the safety of third parties and the environment, and secondly, predict and prevent any emergency situations.

It is possible to cope with such large-scale tasks through:

- collecting and accumulating reliable information about the technical condition and defects of the facility;

- performing comprehensive assessments of the compliance of the building key components with safety regulations;

- engineering study of technologies and methods for engineering protection of the facility with parallel calculation of the cost of repair and reconstruction work;

- monitoring and inspections of the allowability of operating buildings in various permitted and critical modes.

It is possible to establish literally continuous and fully automated supervision over a facility through various inspection and monitoring practices.

Any project for monitoring the safety of a hydraulic structure presents a clear scope of work. Data obtained from continuous inspections is subsequently used to create plans for preventing emergency situations and ensuring the normal functioning of the building.

Scope of work during inspection

Inspection of a hydraulic structure is a complicated and comprehensive process that includes a vast number of stages:

- collection of information, examination of design documents and materials used during construction of the facility;

- visual inspection of both the facility itself and the adjacent territories as well as main structural components;

- fulfilling visual and instrumental inspections of underwater and above-water parts of the structure;

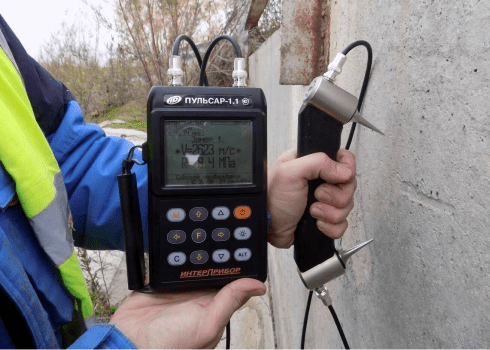

- measurement and research work using specialized equipment and geodetic instruments;

- organization of hydrogeological tests, laboratory analysis of water and soil samples.

Actually, there is much more work. Their features are given in various technical documentation and different GOST standards.

Technical condition monitoring

The automated safety monitoring system for a hydraulic structure consists of numerous software and hardware elements. Various sensors are combined into a kind of observation complex, the functionality of which is ensured with specialized software. Structures of this type are capable of not only identifying accidents and transmitting data to responsible persons, but also predicting off-normal situations over a large time period.

The range of devices used to monitor hydraulic structures can be extremely wide. Most commonly, such equipment includes:

- strain gauges;

- pressure sensors;

- crack gauges;

- piezometers;

- leveling instruments;

- extensometers;

- borehole inclinometers, etc.

The data recorded with the equipment is transferred to servers for subsequent manual and automatic processing. The software supplied complete with monitoring systems makes it possible to solve an impressive range of tasks: from managing the set of sensors to archiving data in information databases. The software works in autonomous mode sending signals to operators when needed.

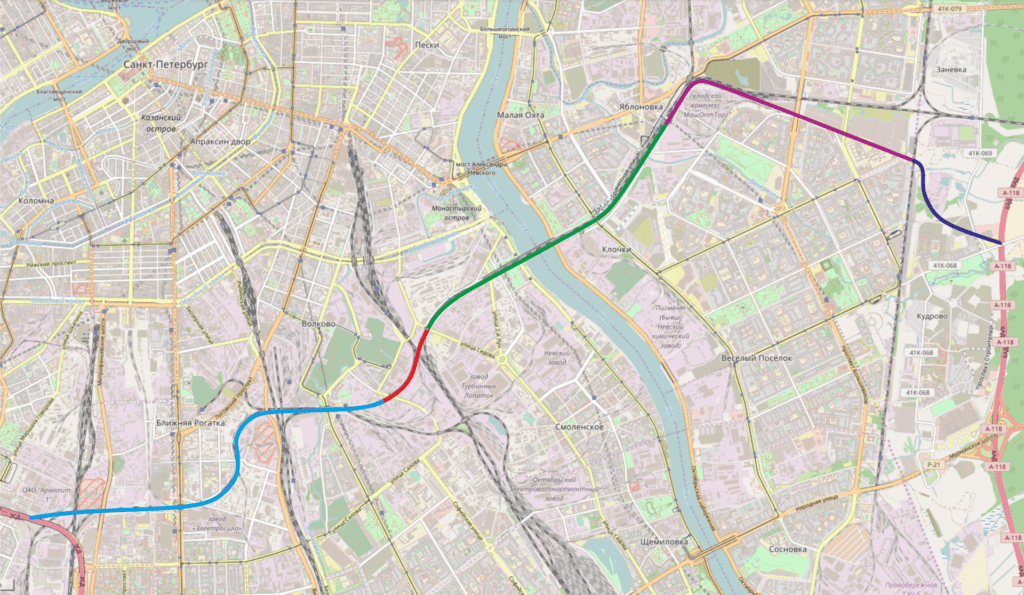

Individual projects for monitoring hydraulic structures

There are truly many options for the tasks related to monitoring the safety of hydraulic structures. Each type of work puts forward special requirements for the level of professionalism and qualifications of contractors. The employees of the Russian Scientific and Technical Centre Integrated Monitoring Systems, LLC are ready to organize all processes and establish automated monitoring for hydraulic structures of any type.

All technical solutions supplied by the Scientific and Technical Centre are designed on the basis of domestically produced equipment. The company cooperates with private customers and government agencies providing a full range of services for the design of systems for monitoring safety of hydraulic structures.

Industry Solutions

Our solutions are based on innovative technologies developed by experienced engineers and automation specialists. All our work is fulfilled in full compliance with the requirements of statutory regulations in the field of industrial safety. Our employees in the construction and installation department have undergone professional training and have the necessary permits to perform work even on hazardous, complex and high-altitude facilities.

Our Scientific and Technical Centre Integrated Monitoring Systems, LLC provides modern solutions for monitoring and controlling processes that guarantee the safe operation of facilities in various industries, including:

Contacts

Still have questions?

Shall we discuss the project?

- office 408, 4, lit. K, Fuchika St., St. Petersburg, 192102, Russia

- +7 (812) 775-10-82

- office@ntc-ksm.ru

- Opening hours: Mon-Fry с 9:00 AM до 06:00 PM MSK